Equipment used to lift the conveyor belt, applied in the process of replacing idlers. Mechanical jack with rotating spindle attached to the crown, allowing the load to be lifted by means of a nut coupled to the spindle forming a geared motor. This equipment is driven by electric screwdriver or impact wrench, being very agile and light handling. Its use provides ergonomic handling with safety and practicality for the professional who uses it, adding productivity gains and reducing the maintenance time of belt conveyors. Patented equipment.

ADVANTAGES:

SAFETY

ERGONOMICS

AGILITY

PRACTICALITY

PRODUCTIVITY

EFFECTIVENESS

References:

4019-WSJ (no. 1): application on belts with dimensions from 24″ and up to 42″

4020-WSJ (no. 2): application on belts with dimensions from 48″, 54″ up to 60″

4021-WSJ (nº3): application on belts with dimensions from 72″, 80″ up to 100″

4022-WSJ (no. 4): application on belts with dimensions below 24″

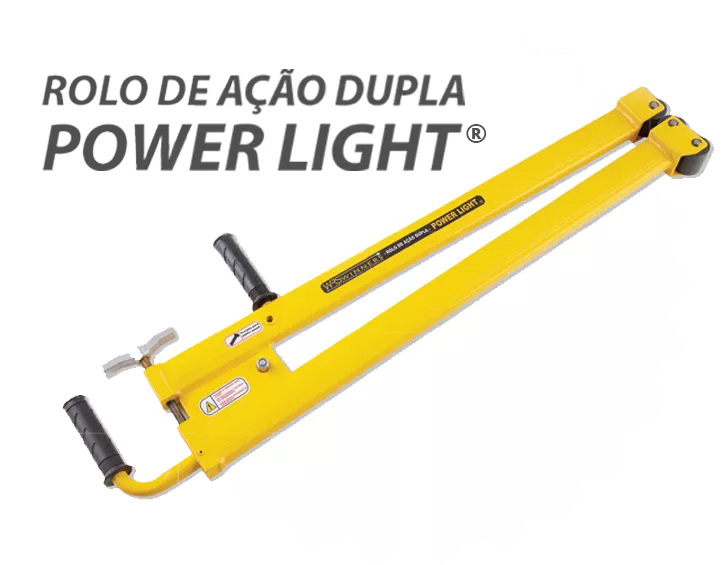

Winners introduces this innovation, the world’s first double-acting roller made of aluminum alloy. Manufactured in a special alloy exclusively developed for its production, this tool is a high technology project developed by the Winners’ Mechanical Engineering team.

Besides the various laboratory compression tests, we went on site to test its efficiency and resistance. The tool was tested for 2 years in big companies of the mining sector, which successfully approved the product.

Pioneer in the development of this tool, Winners guarantees its quality and assures its patente, providing more Trust to the customers.

ADVANTAGES:

75% WEIGHT REDUCTION

HIGH RESISTANCE

ERGONOMICS

AGILITY

SAFETY

PRODUCTIVITY

ECONOMY

4 SIZES

COMES WITH A BAG FOR PROTECTION AND TRANSPORT

Applied in the maintenance process, promoting the efficient joining of rubber pieces in splicing and repairs of textile conveyor belts, preventing air pockets.

Technical specifications of the Power Light Double-acting Roller:

| Referência | Descrição | Peso | Utilizado em correias transportadoras |

|---|---|---|---|

| 14101 | Rolo de Ação Dupla Power Light - 1 | 3,700kg | De até 60" / 1600mm larg. |

| 14102 | Rolo de Ação Dupla Power Light - 2 | 4,400kg | De até 80" / 2000mm larg. |

| 14103 | Rolo de Ação Dupla Power Light - 3 | 5,300kg | De até 100" / 2500mm larg. |

| 14104 | Rolo de Ação Dupla Power Light - 4 | 2,800kg | De até 30" / 800mm larg. |

| Obs: as ferramentas devem ser utilizadas em pares para alcançar as medidas especificadas | |||

IRON HAND® II

This tool is used to facilitate the transport of rollers with diameters ranging from 80 mm to 220 mm, and lengths from 720 mm to 1250 mm. Making the transfer and overall handling of the rollers more agile. With a significant improvement to the comfort design and with workplace safety in mind. Greatly reduces the risk of injury (crushing and loss of limb) during roller maintenance. Applied when performing the conveyor roller transport, speeding up the roller exchange process, with significant improvement in ergonomics and safety, drastically reducing the risk of accidents (crushing and/or loss of limb).

ADVANTAGES:

• ERGONOMICS

• SAFETY

Reference

- 18010-WSH

- 18011-WSH

IRON HAND®

Device developed for handling conveyor belts’ troughing and return idlers. Its use makes it easier to carry the idlers, safely fitting around the shafts. It increases work effectiveness and prevents accidental crush injuries to limbs.

ADVANTAGES:

• ERGONOMICS

• SAFETY

• AGILITY

Reference

- 17010-WSH

- 17011-WSH

SOCKET SET

It is used to turn and tighten bolts in fasteners applied in the process of conveyor belt splicing, mechanical coupling (electric screwdriver or torque wrench). Application of internal/ external parts of nut – screw.

Reference

- 17018-WKP: 2” for application in a screwdriver

- 17019-WKP: 2” ½ for application in a screwdriver

- 17020-WKT: 2” ½ for application in an impact wrench

- 17021-WKT: 2” for application in an impact wrench

PUNCHER

Set with 6 spare punches. It is used in the process of punching canvas conveyor belts. Various applications such as (Application of clamp fasteners/ Fixation of side guides / Installation of bucket elevators), mechanical coupling through (Electric drills).

Reference

1100-WJP

Hole dimensions

- 10,00mm

- 12,00mm

- 14,00mm

- 16,00mm

- 18,00mm

- 20,00mm

STRIP PULLER

Conveyor stripper, tool developed to be used in the mechanical process of removing the canvas from conveyor belts. It provides safety and efficiency in the work performance.

Reference

- 17002: 310mm

- 17003: 209mm

STRONG GRIP – PLIERS

Used in the preparation of the area to be vulcanized in conveyor belt splices. High mechanical resistance, the weight of the lever is equally distributed. Its use provides an excellent accomplishment of the process of conveyor rubber/ canvas opening, making the work safer and faster.

Reference

- 17001-WGT

HAWK KNIFE

Used in the industrial process of cutting rubber/ textile material, conveyor belts. Preparation of various areas to be vulcanized, used to cut canvas belts, a process of preparation for the vulcanization of the conveyor splices.

Reference

- 2570

SPIN LEVER

A tool for spinning the conveyor belts traction pulleys. pplied in the process of refurbishing the pulleys cover, both on site and in repair shops. Its use provides excellence in work performance, with safety and reduction of physical and mechanical effort.

Reference

- 3012